DecoUni3®

types 37015 and 38015

General

| Saw blades | 1 or 2 pieces |

| Diameter |

37015 Ø 700 mm 38015 Ø 800 mm |

| Saw power motor | 15 kW |

| Saw stroke |

37015 250 mm 38015 300 mm |

| Water consumption | 30 – 60 litre/blade/min. |

| Number of operators | 1 |

| Weight | > 3.000 kg |

Technical description

This single-operator machine enables the user to cut a wide variety of stone and brick products. Slips, half bats, half bricks, brick extensions, slip returns and brick specials are just some of the options.

The basic material (up to a height of 250 mm) can be freely positioned on the indexing table, as long as it does not exceed the table’s dimensions. There are hardly any size restrictions.

Thanks to its universal range of applications, this machine offers more flexibility than other models. This machine was often applied as a starting machine and reconsidered as the slip return cutting machine next to the additionally purchased ( or rented ) bulk slip cutter to cope with the growing demand. However, the DecoBasic® has now taken over its destination since the introduction in 2009.

When the annual requirement exceeds half a one million products, however, switching to the other machines is justified. The DecoUni® 3 is particularly suitable for cutting hard materials: a continuous feeding process is no quicker than the intermittent movements of the DecoUni®3 when hard materials are involved.

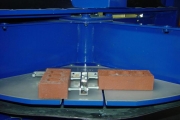

A single operator can load and unload the products. The machine is equipped with an indexing table for this purpose, which has 4 positions for 2 bricks of max. size 250 x 120 mm. After loading, the table makes a quarter turn to perform the next cutting cycle. Each of the quadrants can be fitted with a backstop on pins: four S(traight) L(ine) templates are supplied as standard for the cutting of slips, half bricks and slip returns.

Four cycles per minute can be achieved for soft materials, which translates into e.g. 8 slips per minute. In practice, the production rate is somewhat lower.

Another fundamental difference with respect to the other Deco® machines is the position at which the saw blade makes contact with the product. The saw blade (min. Æ: 700 mm) cuts horizontally into the material from the centre of the saw housing. This leads to a relatively low radial load, which makes it possible cut hard bricks using 2 saw blades simultaneously, while consuming less than 15 kW of motor power.

The 37015 type can be equipped with two Æ 700 mm or Æ 800 saw blades. This helps increase the cutting length from 250 mm (with Æ 700 mm) to 300 mm (with Æ 800 mm). Our 310022 type provides even more power (22 kW), and the 200 mm-larger saw blade diameter provides a further 100 mm cutting length (bringing this to 400 mm).

The DecoUni®3 is therefore not only interesting to the ceramic industry, but also to sectors such as the lime-sand stone, cement and natural stone industries.

Brief summary:

| No. of saw blades | 2 |

| Distance between the saw blades | 150 mm |

| Core thickness of saw blade | 3.5 mm |

| Segment width of saw blade | 4.5 mm |

| Saw blade bore | ø 60H7 mm |

| Saw unit | 15 kW direct drivenSaw motor protection + thermal relay + built-in PTC control system + control of Amps value input (with optional inverter) |

| Saw blade diameter | ø 700 and ø 800 mm |

| Peripheral velocity under load | 36,5 en 39,8 m/s resp. |

| Peripheral velocity of saw blade | 35 / 50 m/s resp. (with optional inverter) |

| Maximum saw cut length | 250 – 300 mm respectively |

| Product dimensions at SL jig | 300 x 120 mm & smaller, height 40>.<260 mm |

| Cutting height range at SL jig | 40 – 250 mm (infinitely adjustable) |

| Clamping range | 500 x 400 mm |

| Hydraulic drive | 1.5 kW |

| Number of pumps | 2 |

| Table diameter | Ø 1 500 mm |

| Width front-right side of table | 360 mm |

| Table rotation drive | 1.5 kW planetary drive brand Brevini |

| Weight | 2 750 kg depending on specs |

| Length | 2 798 mm |

| Width | 2 593 mm |

| Height | 2 110 mm |

| Height with hood open | > 3 200 mm |

| Connections | according footprint 08.04.2004 |

| No. of free memory spaces | 20 |

| No. of frequency controllers | 3 |

| Operator’s working height | 900 mm, depending on brick size |

| No. of footrests | 3, elastic |

| Maximum cutting speed | 6.0 m/minute (infinitely adjustable) |

| Cutting speed | dependent on saw motor load ( “optifeed” option) |

| Consumed current | 8 – 30 A, readout via digital display on optional inverter |

| Entry and exit stroke | 0 – 250 / 300 mm (infinitely adjustable) |

| Speed of entry and exit stroke | 0.1 – 6.0 m/minute |

| Control cabinet components | PLC and Touch Screen made Siemens |

| Operating instructions | included, in all languages |